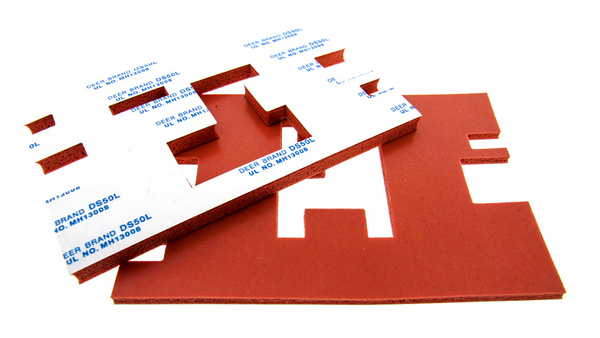

Flexible Heater Mounting Methods

The most popular form of mounting for flexible heaters is pressure sensitive adhesive (PSA). PSA is a relatively thin flexible material with single- or double-sided coating. PSA bonds easily to a variety of clean and dry surfaces with pressure. PSA is self-bonding, as it does not need other materials (solvents or water) to activate the adhesive. The bond is directly influenced by the amount of pressure which is used to apply the adhesive to the surface. PSA is a popular solution due to its ease of use and its low cost compared to traditional mounting systems. Further advantages for PSA include uniform thickness, thinner and lighter materials, cosmetically appealing as opposed to mechanical fasteners, and overall reduction of assembly time.

The type of adhesives recommended for flexible heater PSAs are acrylic and silicone. Both are exceptional for high heat applications. Acrylic is the more cost effective of the two, but silicone offers the highest performance of the two with temperature resistance, shear, and solvent/UV resistance. Rubber is another option for an adhesive, but it is not recommended for high heat applications.

Additional Mounting Options

Room Temperature Vulcanizing (RTV) silicone is a silicone rubber that is generally supplied as a one-part system with a wide viscosity range. It’s comprised of organic and inorganic compounds that make it one of the most stable organic adhesive products available today.

These adhesives are resistant to high temperatures and are extremely flexible compared with other industrial adhesives. RTV silicone adhesives have many advantageous properties. They are incredibly flexible (depending on the temperature) and have a wide operating temperature range. They are resistant to harsh weather conditions, humidity, mold, and mildew. RTV Silicones have a 40-year life span and a high degree of elongation; they are easy to dispense, even in cold temperatures, and are VOC compliant with excellent UV and thermal stability properties.

Rubber Grommets

Rubber grommets are designed to eliminate risk for flexible heater chaffing on installs that feature rough edges or sharp cutouts. Keep your flexible heaters protected with flexible grommets by easily snapping the grommet into place around the flexible heater and bonding substrate. This grommet solution is manufactured for easy installation and provides your application with extra protection for a long-lasting electrical solution.

Snap Nylon Grommets

Standard nylon snap bushings protect flexible heaters from chafing against sharp edges. Bushings are made to withstand push back force of up to 35 pounds.

Velcro Fasteners

Velcro fasteners are easy to use, safe, and maintenance free. There is only a minimal decline in effectiveness even after many fastenings. One notable disadvantage is that Velcro fasteners tend to accumulate hair, dust, and fur in their hooks after a few months of regular use. The loops can become elongated or broken after extended use. The hooks often become attached to articles of clothing, especially loosely woven items like sweaters.

Maximize Your Flexible Heater's Performance with the Right Mounting!

Pressure Sensitive Adhesive (PSA) is the go-to mounting method for flexible heaters, offering an easy, efficient, and cost-effective solution. Choose between high-performing acrylic or silicone adhesives, with the latter boasting superior resistance attributes.

Request a Quote Request Design Support Request More Information