Silicone Rubber Heaters

Epec silicone rubber flexible heaters can be custom designed to various shapes and sizes, ranging from 1” X 1” to 18” X 24”. If larger sizes are needed, then switching from an etched element to a wire element would be required. Based on the element used, the overall average thicknesses are 0.030" (etched element) to 0.056" (wire wound).

The etched or wire circuit is attached to power leads with solder and then vulcanized between two layers of silicone rubber, resulting in a completely homogenous unit. The silicone offers protection from physical damage such as scraping or scuffing and acts as a moisture barrier to allow for operation in wet and outdoor environments. Silicone is also resistant to most chemicals.

We offer multiple heating elements for silicone heaters such as stainless steel 304, CuNi44, and Inconel600, with excellent dielectric properties and operating environments between -70°F (-56.6°C) and 392°F (200°C). It should be noted that silicone heaters have a delay of transfer from the resistive foil or wire to the mounting surface.

Current Specifications for Silicone Heaters

- Maximum Watt Density: 60 W/in²

- Maximum Operating Temperature: 392°F (200°C)

- Minimum Operating Temperature: -70°F (-56.6°C)

- Wattage Tolerance: ±10%

- Dielectric Strength: 1000 VAC

Types of Flexible Silicone Rubber Heaters

Wire-Wound Heaters

Flexible silicone rubber heaters use wire-wound elements (resistance wire) laminated between silicone rubber to ensure a uniform heat profile and excellent physical strength. This technology is typically used in lower volume or larger size applications as it is easier to conform to the size and shape of the application, avoiding holes and cutouts, or to concentrate the heat profile in a specific section or sections of the heater as required. Wire wound design is a solution to the limitations or etched foil technology.

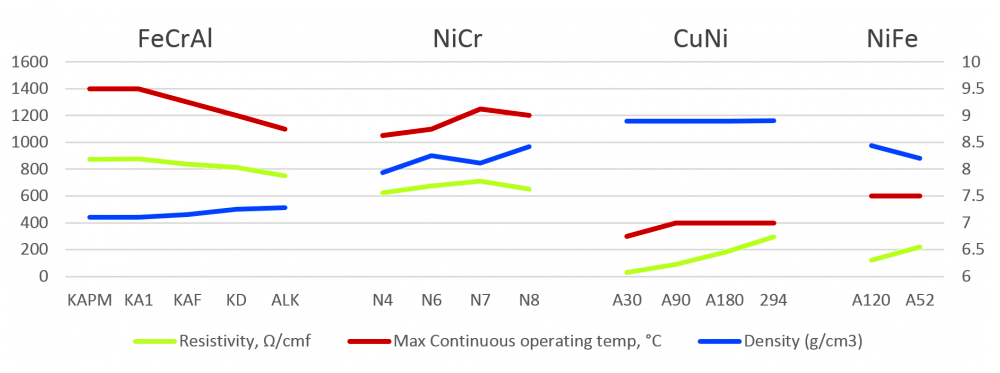

Below are the different types of resistance wire used in wire wound flexible heaters.

- Nickel Chrome (NiCr) alloys are the most common material used in silicone rubber heater applications with maximum operating temperatures up to 1,250°C (2,280°F). Typically called Nichrome wire, it is a non-magnetic alloy that has high resistivity and good oxidation resistance.

- Copper Nickel (CuNi) alloys have medium range electrical resistivity and very low temperature-coefficient of resistance so they are typically used in flexible heater applications with maximum operating temperatures up to 600°C (1,110°F).

- Iron Chrome Aluminum (FeCrAl) alloys are high-resistance materials with very good form stability resulting in long element life typically used in applications with maximum operating temperatures up to 1,400°C (2,550°F). Because silicone rubber heaters made with this material will have higher surface loading capability, higher resistivity, and lower density than traditional Nichrome alloys, the heater can be designed with less material to provide weight savings.

* The above data is a representation of the resistance wire temperature.

Etched Foil Heaters

These heaters utilize chemically etched circuits which are laminated between thin sheets of silicone to give even quicker heat transfer properties for applications that require precise temperature control. While etched foil circuits need wider widths to accomplish equivalent resistance of a wire, the traditional print/etch process that has been used in printed circuit board fabrication for decades provides tight spacing control which enables spacing between elements to be as tight as 0.004”. The ability of our design teams to create the precise circuit geometry allows even thermal distribution and precise repeatability through production.

Silicone rubber heaters using an etched foil circuit can provide twice the output wattage of the older wire wound technology. This technology allows us to provide multiple heating zones on the same heater and is also attractive for designs that require watt densities greater than 5 W/in2. in as the foil thickness for the circuit can range from 0.0005” to 0.004”.

The etched foil can be created out of many different types of alloys such as aluminum, stainless steel, nickel-chrome non-magnetic alloys, copper, constantan, and others. Our experience with all of these various materials ensures that we can design and provide the best solution possible for your application.

Applications and Industry Benefits

Silicone rubber flexible heaters are versatile and find application in various industries due to their unique properties and adaptability. Some of the most common applications for silicone rubber flexible heaters include:

- Medical Equipment: Silicone rubber heaters are used in medical devices like blood analyzers, IV fluid warmers, and medical imaging equipment to maintain consistent temperatures for accurate readings and patient comfort. Learn more about this topic here, Flexible Heaters for the Medical Industry – Benefits and Applications.

- Food and Beverage Industry: These heaters are employed in food processing equipment, such as heated food cabinets, warming trays, and vending machines, to ensure food is kept at the right temperature for serving or storage. See more details, Flexible Heaters - The Ideal Solution for the Food Industry.

- Aerospace and Aviation: Silicone rubber heaters are used in aircraft systems, including cabin heating, de-icing applications, and fuel temperature maintenance. View more, Flexible Heaters for Aerospace Industry - Advantages and Applications.

- Automotive: These heaters are utilized in automotive applications like engine oil preheating, battery heating, and heating elements for seats and mirrors to enhance passenger comfort.

- Laboratory and Analytical Instruments: Silicone rubber flexible heaters are found in laboratory equipment, such as incubators, autoclaves, and reaction vessels, where precise and uniform heating is required.

- Industrial Processing: They are used in industrial equipment, such as plastic molding machines, semiconductor manufacturing, and packaging machinery, to maintain specific temperatures during the manufacturing process.

- 3D Printers: Silicone rubber heaters are employed in 3D printers to keep the print bed at an optimal temperature, ensuring better adhesion and reducing the warping of printed materials.

- Oil and Gas: These heaters are used in oil and gas applications for heating pipes, valves, and tanks to prevent freezing or viscosity issues.

- Electronics: Silicone rubber heaters are incorporated into electronic devices, like LCD display heaters, to prevent condensation and improve performance in cold environments.

- Renewable Energy: They find applications in renewable energy systems, such as solar panels, to prevent snow buildup and improve efficiency.

- Refrigeration and HVAC: Silicone rubber heaters are used in refrigeration units to prevent condensation and icing on critical components, ensuring the system's optimal functioning.

Silicone rubber heaters and polyimide (also known as Kapton®) flexible heaters are both popular choices for applications that require flexible heating solutions. Each type of heater has its unique advantages.

Benefits Of Silicone Rubber Heaters Over Polyimide Flexible Heaters:

- Better Temperature Range: Silicone rubber heaters have a broader temperature operating range compared to polyimide heaters. As mentioned earlier, silicone rubber heaters can typically operate from -60°C to 230°C (-76°F to 446°F), whereas polyimide heaters usually have a narrower range, typically from -70°C to 260°C (-94°F to 500°F). This wider temperature range makes silicone rubber heaters more versatile for applications in extremely hot or cold environments.

- Improved Flexibility: While both heaters are flexible, silicone rubber heaters tend to be more pliable and have better-conforming properties. They can easily adapt to irregular shapes and contours, making them ideal for applications that require heating non-flat or curved surfaces.

- Faster Heat Transfer: Silicone rubber heaters have higher thermal conductivity than polyimide heaters, allowing them to transfer heat more quickly and efficiently to the target surface. This characteristic reduces warm-up times and improves overall energy efficiency.

- Enhanced Moisture Resistance: Silicone rubber is inherently more resistant to moisture and environmental factors than polyimide. This makes silicone rubber heaters better suited for applications in damp or outdoor environments.

- Chemical Resistance: Silicone rubber heaters exhibit better resistance to various chemicals, solvents, and industrial fluids. In contrast, polyimide heaters may be susceptible to degradation when exposed to certain aggressive chemicals.

- Thicker Construction: Silicone rubber heaters are typically thicker than polyimide heaters, providing extra mechanical strength and durability. This thicker construction makes them better suited for applications where robustness and longevity are critical.

Despite these advantages, it's essential to note that the choice between silicone rubber and polyimide flexible heaters depends on the specific requirements of the application. For instance, polyimide heaters may be more suitable for ultra-thin applications where space is limited, or in cases where higher temperature resistance beyond the capabilities of silicone rubber is needed.

Ultimately, both silicone rubber and polyimide heaters have their merits, and the selection should be based on factors like temperature range, flexibility, chemical exposure, cost, and the environmental conditions of the intended application.

Elevate Your Heating with Epec's Custom Silicone Rubber Heaters!

Our state-of-the-art silicone rubber heaters are tailored for precision, adapting from sizes 1” X 1” to 18” X 24” with unparalleled adaptability. Whether it's for medical devices, aerospace, automotive, or industrial processing, our heaters promise robustness and efficient thermal delivery, even in challenging environments.

Request a Quote Request Design Support Request More Information