Flex & Rigid-Flex PCBs - Applications and Cost Drivers Webinar

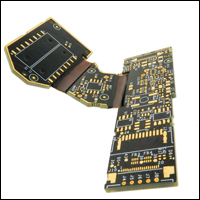

This webinar will review primary design requirements that are best served by the utilization of flex or rigid-flex circuit boards within a given design.

We will look at a wide variety of flex and rigid-flex applications used throughout the medical, avionics, instrumentation, industrial controls and sensors, automotive, wearable devices, and military market segments.

Along with addresses the primary cost drivers and factors that can impact the per part cost.

Webinar Agenda:

- Design Drivers

- Packaging

- Reliability

- Signal Integrity

- Reduced Component Requirements

- Simplified Assembly

- Cost Drivers

- Overall Part Dimensions

- Part Shape

- Layer Count

- Impedance Control Requirements

- Added Features:

- Stiffeners (Polyimide & FR4), PSAs, Epoxy Strain Reliefs