Epec Continues Technology Equipment Investments with Fischerscope

Release Date:

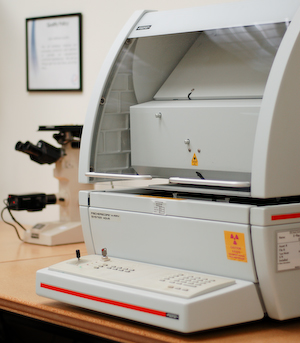

[October 1, 2008: New Bedford MA] One of Epec's latest equipment purchases, the Fischerscope XDVM-W, is now fully operational, to quickly and easily measure the coating thickness and alloy composition of virtually any metal coating system. This newest device better ensures that our customers products are consistently built to the right specifications, supported by in depth analysis.

The installation, part of Epec's newest $1mm Capital Investment Program, gives Epec's Quality Department another important measurement tool, to improve product delivery, proactively prevent quality problems, and improve our speed at responding to quality challenges.

The Fischerscope measures the thickness of surface finishes. (Silver, gold, tin, tin-lead, nickel), the thickness of underlying metals. (Copper, nickel), the percent ratio of present metal elements, and detects contaminate metals.

"Over the past year, Epec's quality team has made significant improvements throughout our global supply chain, and our quality metrics have improved by more than 30% year over year," shared Chris Perry, Epec's Quality Manager. "We understand that surface finish thickness and inorganic surface metal contaminants can directly affect board solderability, and are a growing concern throughout the electronics sector."

"With the Fischerscope purchase and operation, we can meet and exceed the level of service to our customers through improved qualitative analysis, instant data results, and quicker lead times."