Company Overview

At Epec, we have a powerful story to tell - a history of great achievements, world class talent, and innovative breakthroughs. Most importantly, we have a history of helping our customers deliver their high quality products to market, faster.

Our 70 year history of reliability and financial stability enable our continuous investment in people, technology, and new ideas that make it easier for our customers to do great work.

Custom, build to print electronics is our entire business, and flexibility is at the heart of how we meet our customer’s dynamic needs. To ensure the most accurate, timely, and cost effective design and manufacturing process, we have engineered flexibility into the very fabric of our company. We understand the complete product design and manufacturing process, to deliver the solution that fits the go to market strategy.

We have built a global team of engineers, designers, R & D innovators, product managers, manufacturing/supply chain professionals, quality assurance personnel and sales/customer service staff, all of whom are experts in their fields. Rather than limit production capacity to our US and UK manufacturing centers, we have developed UL certified world class production facilities which are ISO-9001, QS-9002, TS-16949, with aligned technology roadmaps and quality systems.

Epec is proud to be one of the fastest growing companies in the electronics sector, with more than 100 passionate and dedicated employees throughout North America, Asia, and Western Europe.

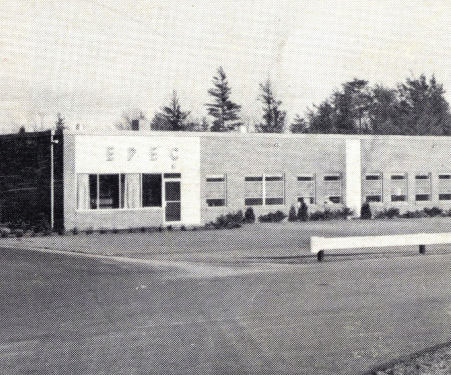

Delivering Quality Since 1952

Our Family of Companies

At Epec, we have multiple businesses that makeup our family of companies. Visit their websites to learn more about them and the products and services they offer.