High Reliability Keypads - Design Factors That Affect Performance

By Paul Knupke - Epec Engineered Technologies

Custom low-profile keypad assemblies with the right combination of material and construction choices can provide high reliability user interface keypads. Prepare to discover the differences between high reliability custom keypad assemblies and those keypad assemblies which fail prematurely.

There are a number of factors that adversely affect keypad reliability. Three of these factors are the biggest offenders that adversely affect keypad reliability which include:

- External contamination entering the switch cavity.

- Internal contamination in the switch cavity.

- Exceeding the switch contact point electrical ratings.

Prior to examination of these factors, a review the basic construction styles used in custom low-profile keypads is necessary.

Custom Low-Profile Keypads

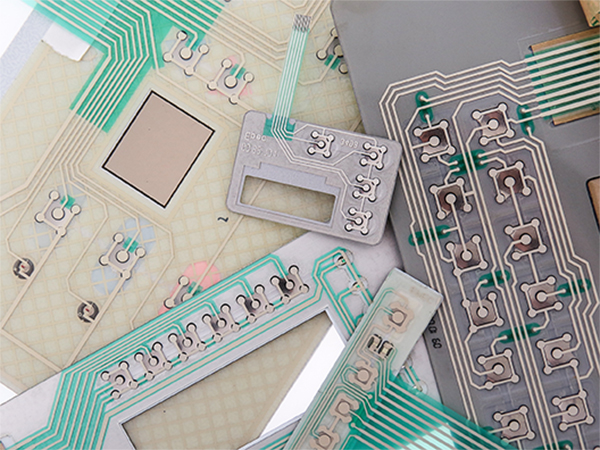

Custom low-profile keypad assemblies usually fall into two general categories. One type of low-profile keypad assembly is the conventional flexible printed membrane keypad where the switch circuitry is printed silver conductive polymer inks screened onto 1.25 mm (5-mil) polyester sheets (see Figure 1). Two opposing polyester circuit layers are separated by a thin adhesive/polyester layer with a hole at each switch location. Finger pressure at the switch location deforms the front circuit layer through the hole and completes the circuit to the bottom circuit layer. Tactile feel is usually provided by a metal snap dome or an embossed dome formed in a polyester sheet, sometimes called poly domes.

Figure 1: Conventional flexible membrane keypad with printed silver conductive ink.

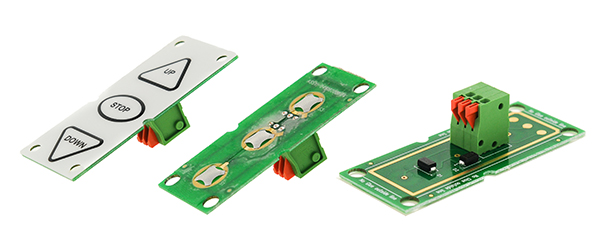

The second type of low-profile keypad assembly incorporates a printed circuit board with metal snap domes (see Figure 2). All of the keypad’s circuitry is on the printed circuit board and the snap domes provide tactile feel as well as a method of completing a circuit path for individual switch. Either style of the keypad can be completed by a decorative graphic overlay or another actuating mechanism such as a plastic key top or a molded rubber key top.

Figure 2: Keypad assembly incorporates a printed circuit board with metal snap domes.

External Contamination

The first factor which we examine that adversely affects keypad high reliability is external contamination entering the switch cavity (see Figure 3). External contamination always causes problems. External contamination can take the form of non-conductive “dirt” such as paper lint, dust, and other airborne particles, or can be liquid with suspended “dirt” or dissolved contamination.

Figure 3: External contamination can enter the switch cavity.

Each style of low-profile keypad contains a volume of air inside the switch area, usually called the switch cavity. When a finger presses on the switch location to close the switch, the air inside of the switch cavity needs to reduce in volume.

If the switch cavity is completely sealed, the air inside the switch cavity cannot escape. Reduced air volume in a sealed switch cavity increases switch cavity air pressure and diminishes the tactile feel by pushing back. The easy solution to maintaining tactile feel is providing a path for the switch cavity air to escape.

External vents in screen printed silver membrane keypads can be accomplished by cutting narrow air channels in the spacer layer between the silver printed polyester circuit layers from the switch cavities and a peripheral edge. External vents in printed circuit board keypads can be provided using a via hole in the printed circuit board under the snap dome.

Solving one problem – loss of tactile feel – creates a path for external contamination to enter the switch cavity. Pressing the switch exhausts some of the switch cavity air to the outside of the keypad. When the finger is removed a partial vacuum is formed in the switch cavity and sucks in outside air along with any contamination in the area. External contamination, either solid or liquid, will prevent the proper electrical switch closure because most contamination is non-conductive. Any switch contact point with a non-conductive coating will result in higher switch resistance, increased electrical switch bounce, or all the way to a complete open switch.

Maintaining tactile feel and prevention of external contamination is achievable but certain design and construction details must be used. Understanding the cause of the problem is always the first step in solving the problem.

On a side note, another style of custom keypad construction is a conductive rubber keypad commonly found in cable TV remote controls and other low cost applications. The rubber key tops and surrounding rubber boot has carbon-filled molded rubber “pills” or “pucks” on the bottom side under the switch keytops that shorts bare circuits on the printed circuit board.

This style of keypad is not considered as a high reliability keypad because, by design and construction, the keypads are not sealed and prone to limited service life due to external contamination accumulating on the switch contact surfaces. As the conductive rubber keypad is not considered high reliability, we will not consider this construction for further discussion here on high reliability keypads.

Internal Contamination

The second factor that adversely affects keypad high reliability is internal contamination in the switch cavity. Internal contamination takes for form of oxide growth on the switch contact surfaces. All common metal oxides with the exception of silver are highly resistive or non-conductive. A non-conductive switch surface makes a very poor electrical switch.

Silver printed polyester membrane switches are inherently immune from non-conductive oxide growth as silver is the only common metal whose oxide is fully conductive. In printed circuit board based metal snap dome keypads; there are other conductors with metal surfaces that need control of oxide growth. In this style of keypad, the switch surfaces are on the printed circuit and the metal switch dome.

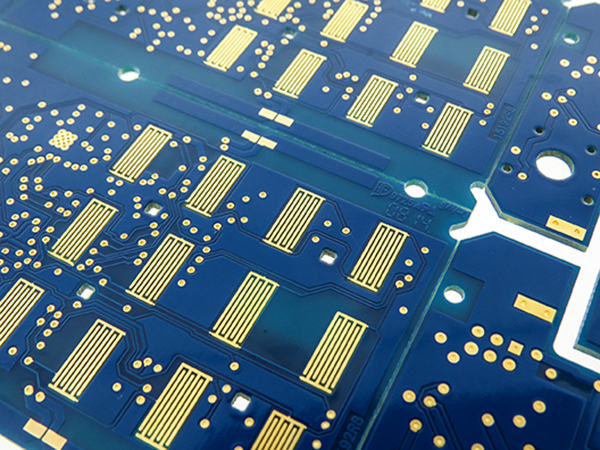

Non-conductive oxide growth on printed circuit boards is easily prevented using gold plating over nickel barrier plating. Readily available electro-less gold plating process provides two to four micro-inches of gold thickness. Our experience shows that a minimum of 5 micro-inches of gold thickness is necessary because the metal snap dome feet wipe the gold surface and will wear through thinner gold plating (see Figure 4).

Figure 4: Switch contacts need to have a minimum of 5 micro inches of gold to prevent oxidation.

Virtually all metal switch domes today are stamped from stainless steel alloy. A common misperception about stainless steel is rust does not easily form on the surface of stainless steel. However, the opposite case is true as visible rust is prevented by the formation of chromium oxide “rust” on the surface of the stainless steel. A small percentage of chromium is found in all stainless steel alloys. The chromium oxide is transparent and seals the surface so that iron particles do not form iron oxide. The chromium oxide is what makes stainless steel “stainless”.

As with most common metal oxides, chromium oxide is non-conductive and does not make a suitable switch surface. Chromium oxide can be worn off by repeated wiping action of the metal snap dome feet, the chromium oxide reforms quickly. Stainless steel domes can be plated with nickel, and nickel does a respectable job of preventing chromium oxide growth. However, gold plating prevents chromium oxide growth and electrically performs better as a switch surface. The writer has 28 years’ experience with gold plating of stainless steel domes and found out early on that standard gold plating processes cause major mechanical damage to highly stressed, punched stainless steel snap domes.

Standard gold plating chemistry is hydrogen based and causes hydrogen embrittlement in stainless steel. Hydrogen embrittlement severely impacts operating cycle life of metal snap domes. In controlled tests that I have performed, hydrogen embrittlement has reduced the cycle life of metal snap domes by as much as 90 percent. Fortunately, the correct choice of gold plating chemistry and process completely eliminates the hydrogen embrittlement on our gold plated stainless steel snap domes.

Blindly specifying gold plated snap domes without knowledge of the correct chemistry and process choice is a disaster waiting to happen. My experience shows most keypad application designers are not aware of the chromium oxide problem or potential cycle life problem, and few customers perform life cycle tests to validate their specifications and designs.

Exceeding The Switch Contact Point Electrical Ratings

The third factor that adversely affects keypad high reliability is exceeding electrical ratings for the switch contact surfaces. Low profile keypads are intended for logic-level circuits. Excess open circuit voltage, excess closed circuit current or reactive components in the switched load such as inductors or capacitors will quickly deteriorate the switch surfaces.

Once the switch surfaces are damaged by exceeding electrical ratings, switch performance problems such as intermittent switch operation, long contact bounce on make or break, and high resistance will occur and is irreversible. Although this factor is discussed last of the three factors, this factor’s problems trump all the other factors adversely affecting keypad high reliability.

When high voltage high current or reactive loads are switched, loads must be isolated from the keypad’s switch surfaces by solid state relays or electronic buffering. Designers wouldn’t exceed ratings on other electrical parts, and keypads should not be handled any differently.

Summary

In summary, high reliability keypad’s operating life should not be shorter than the application containing the keypad. Conversely, the application is only as good as its keypad.

The keypad deserves as much design attention as the rest of the application because it is the user interface. The best part about high reliability keypads is the solutions to the factors discussed here are either very inexpensive or add no cost for knowledgeable and competent keypad suppliers.

Does Your Application Require a High Reliability User Interface Keypads?

Our team of experienced engineers is here to help you design a custom user interface solution, from a conventional flexible membrane keypad with printed silver conductive ink to a keypad assembly incorporating a printed circuit board with metal snap domes.

Request a Quote Request Design Support