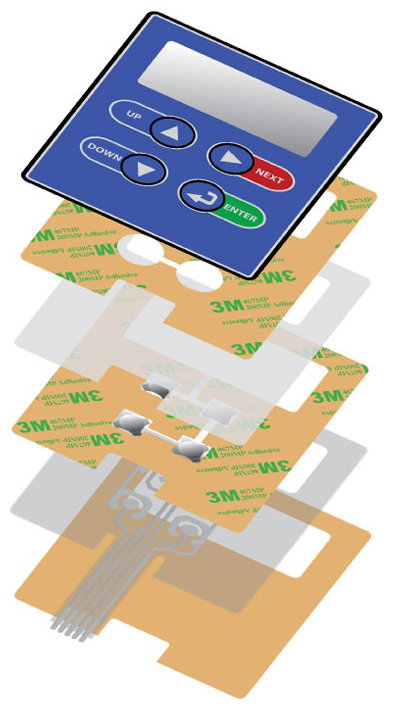

Membrane Switches and Graphic Overlay Capabilities

Our Membrane Switch and Graphic Overlay capabilities include die cutting, embossing, laminating, forming, machining, serial stamping, and bar codes.

We offer a variety of substrates and special features can be incorporated to accommodate your branding efforts. Such as Embedded LED, Fiber optic and electroluminescent (EL) backlighting are options that can save you money, time and/or board space.

Tooling costs are low because we use steel rule dies to cut the circuit layers and overlays to your exact design specifications. You can even use multiple custom overlays with a single circuitry design lowering your overall cost of membrane switch design and manufacturing.

Processes

Die Cutting

- Unusual shapes

- Rounded corners

- Hard dies for metal parts

- Steel rule dies for flexible materials

- Thermal dies for vinyl substrate

Embossing

- Adds three-dimensions to printing for unique identification

Laminating

- Protects printed nameplates, overlays, and decals

- Subsurface printing on flexible substrates can be laminated on aluminum nameplates for increased durability and protection

Forming

- Bending to your specifications

Machining

- Full in-house machine shop

- Manufacture any rectangular, square, or round metal nameplate, serial / VIN plate, or control panel without additional tooling charge.

Serial Stamping

- Serial, vehicle identification numbers (VIN) or model numbers can be stamped on flexible or metal substrates

Bar Codes

- Bar codes can be printed on any nameplate, serial / VIN plate, control panel, or graphic overlay, on any surface type

Materials

Metals

- Aluminum

- Anodized Aluminum (clear or black)

- Stainless Steel

- Brass

- Metalphoto

Adhesives

- Permanent, pressure-sensitive acrylic

- Special adhesives for application to powder coated surfaces or low surface energy plastic

- Various foam thicknesses to adhere to rough surfaces or to dampen vibrations

Flexibles

- Polycarbonate

- Polyester Film

- Vinyl

- Foil

- Adhesive-Backed Litho Paper

- Polystyrene

Custom Solutions for Your Application

Optimize your design with our comprehensive membrane switch and graphic overlay services. Low tooling costs, multiple materials, and special features to match your branding. Request a quote today!

Request a Quote Request Design Support Request More Information