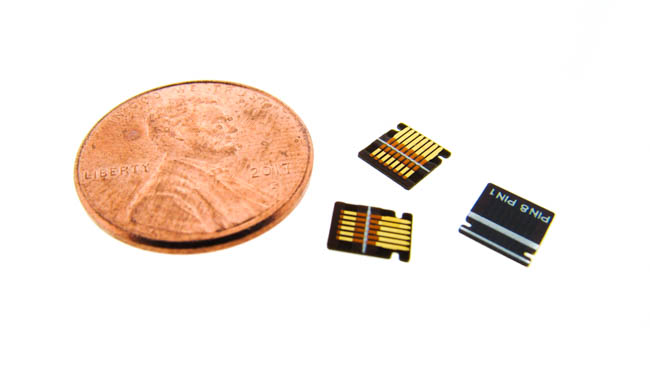

Flexible PCB Microcircuits

As technology advances devices get smaller and the speed requirements of data transmission on circuit boards increases. Every flexible PCB is designed to perform a function inside an allotted space, but they also need to be manufacturable, need to be held to strict mechanical tolerances, and need to be cost effective.

With component sizing getting smaller every year, it allows very small flexible PCBs to include significant functionality along with being a passive component to provide connectivity in certain applications.

How Small Can a Flexible PCB Be?

The size of the microcircuit depends on the application but some of the key items that are important to many customers are:

- Keeping a very tight outline tolerance.

- Impedance values that can be held to +/-5% even in high volume applications.

- Gold plating for use in connector terminal applications.

- Using LPI solder mask on flexible substrate to keep solder mask damns intact.

- Adding small stiffeners to allow one end of the material to be rigid.

- Microcircuits require very fine line and spaces which requires specialized etching equipment.

- In-house punch press and tooling manufacturing capabilities improves our time to market.

Miniature Flexible PCB Capabilities

The following table outlines our general capabilities for flexible microcircuits. However, every application is different so please contact us with your design questions so that we can review your application parameters.

| Product | Miniature Flex Circuits |

|---|---|

| Smallest PCB Size | 5mm x 5 mm |

| Line Width and Spacing | 0.002" (0.05mm) |

| Copper Thickness | 1/4 oz, 1/3 oz, 1/2 oz 1 oz, 2 oz, and higher |

| Via/ Drill Size | |

| Minimum Drill (Mechanical) Hole Diameter | 0.004" (0.1 mm) |

| Minimum Via (Laser) Size | 2 mil (0.05 mm) |

| Minimum Micro Via (Laser) Size | 3 mil (0.07 mm) |

| Solder Mask/Coverlay | |

| Solder Mask Bridge Between Dam | 3 mil (0.08 mm) |

| Solder Mask Registration Tolerance | 2 mil (0.05mm) |

| Coverlay Registration | 8 mil (0.20 mm) |

| PIC Registration | 7 mil (0.18 mm) |

| Stiffener | |

| Stiffener Registration | 8 mil (0.28 mm) |

| Thickness Tolerance | 10% |

| Smallest Stiffiner Size | 0mm x 0mm |

| Impedance | |

| Impedance | +/- 8% |

| Steel Rule Die (SRD)) | |

| Outline Tolerance | 4 mil (0.1mm) |

| Minimum Radius | 4 mil (0.1 mm) |

| Inside Radius | 20 mil (0.51 mm) |

| Punch Minimum Hole Size | 28 mil (0.7 mm) |

| Tolerance of Punch Hole Size | +/- 2 mil (0.051 mm) |

| Slot Width | 20 mil (0.51 mm) |

| Tolerance of Hole to Outline | +/- 2 mil (0.05 mm) |

| Tolerance of Hole Edge to Outline | +/-3 mil (0.07mm) |

| Minimum of Trace to Outline | 8 mil (0.20 mm) |

| Electrical Testing | |

| Test Voltage | 50 - 300V |

| Surface Finishes Available | |

| Hard Gold, ENIG, ENEPIG, OSP, Immersion Silver, Immersion Tin, Plating Tin | |

Applications for Flex Microcircuits

The continuous miniaturization of devices has driven printed circuit boards to become smaller and denser and require more capabilities. Applications we supply mini flexible PCBs include:

- High speed digital / RF / microwave connectors

- Industrial sensors

- Instrumentation consumables

- Medical devices - wearables

- Hearing aides

- Semiconductor packaging

- RFID Tags/antennas

- And many more...

Epec is a leading experienced miniature printed circuit board developer and manufacturer with an eye on industry tolerances and customer service. We offer a full design and manufacturing services that can quickly adjust to meet any high or low volume demands you have.

Customized Solutions That Meet Your Project's Needs

Our advanced flexible PCBs meet stringent tolerances and are perfect for space-constrained applications. From medical devices to high-speed digital connectors, our microcircuits deliver unparalleled performance.

Request a Quote Request Design Support Request More Information