Custom Overmolded Cable Assemblies

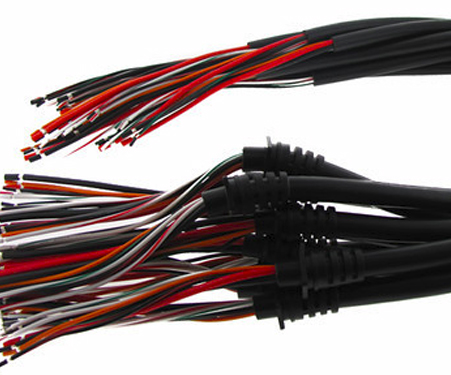

Epec designs and manufactures custom overmolded cables to the highest standards, supporting countless applications. Ruggedized overmolded cables are used across the military, aerospace, medical, and consumer product industries. Overmolded cables are ideal for applications that demand a low-cost and high-reliability solution, especially in wet environments, sealing applications, or where there is a concern for bending and flexure. These cables can range in complexity and size with some examples being low-voltage USB cables all the way through medical imaging harnesses and even higher complexity breakout harnesses that are over 100 feet long.

We support our customers by delivering highly custom solutions quickly and do this in a way that provides high value to our customers. Since the majority of our overmolded cables are completely custom, with 100% customized overmold tooling and in many cases our custom extruded bulk cable, there are considerable manufacturing challenges that need to be managed concurrently. With Epec’s focus on NPI (New Production Introduction) processes, we can help reduce risk and eliminate surprises in our custom cable builds. This includes our design for manufacturing review to address issues such as overmold wall thickness concerns or a crimp terminal incompatibility. We have measures in place to help identify program challenges early in development that could otherwise derail a project.

Economical Pricing for Overmolded Cable Customization

Most of the cost for an overmolded cable is actually in the connector and bulk cable. Copper wire and other assembly materials drive the cost. The overmolded material itself is very inexpensive, and it’s a largely automated process with minimal labor costs. Our demonstrated processes offer value for projects that require high-mix, low-volume all the way up to high-volume projects. Overmolding a cable is an extremely low-cost and high-reliability solution as long as the tooling NRE are accounted for.

Many projects for common industry connectors can benefit from our extensive library of house tooling. Many of these cable assembly projects can be prototyped and manufactured with zero NRE investment in hard tooling from our customers. This is because we already have the tooling built, qualified, and ready to use. These include connector schemes such as USB, banana jacks, RCA plugs, HDMI, RJ45, etc. The only downside is there is typically a cost to modify the house tooling since it is shared amongst other customers and projects.

Custom Overmolded Cables in Stock

Epec designs and manufactures custom cable assemblies in economic order quantities while managing the shipment of raw materials and finished goods. When product is manufactured overseas, it is first consolidated in Hong Kong and then shipped to our corporate headquarters in New Bedford Mass. Materials can be held in inventory and released at predetermined delivery schedules of up to 12 months, shipping directly from our headquarters in New Bedford. This way, Epec can offer custom-built cables at economical prices while pulling from finished stock. When demand increases, inventory is available at our domestic warehouse for same day shipment.

Why Choose an Overmolded Cable?

Overmolding has dramatically changed the appearance and functionality of cable assemblies over the last several decades. Through the utilization of the injection molding processes, overmolding has allowed cable assemblies to have better functionality by:

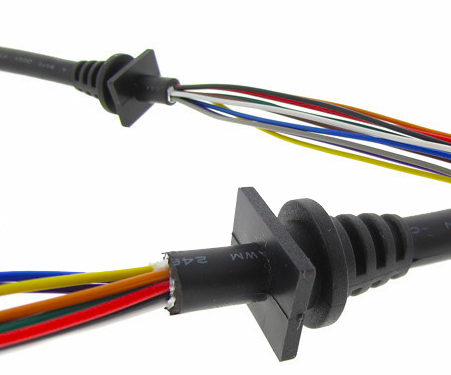

- Allowing them to become impervious to fluids, therefore being able to be exposed to harsher environments.

- Providing them the ability to withstand shock, vibration, and continual flexing without damage to the termination point.

- Using 3D printing, models of the overmold can be quickly and cost effectively created to ensure that the overmold meet the application requirements prior to hard tooling.

Overmolding Design Considerations

When designing cable assemblies, engineers are using the overmolding process for one of two reasons:

- To encapsulate some sensitive piece of equipment or circuit board.

- To provide strain or bend relief from a pinch point or high stress location on the parent cable.

Overmolding can replace grommets as part of the assembly for any point where an assembly needs to be installed through a housing/opening. Overmolds can also be used as a covering for the connector backshells and to protect the termination points including any exposed contacts. Waterproof ratings of up to IP67 and IP68 can be achieved. As the complexity of tooling increases and the number of potential materials that can be used in the overmolding process expands, the overall complexity is compounded and details matter.

Consideration must be given to the material that will be used for the overmold since this will impact the desired appearance and function of the part. Additionally, the operating parameters of the overmolding machine itself must be considered since this can create parting lines, sink holes, or other cosmetic imperfections. If the cosmetic appearance of your part is critical, specialty mold textures and steps can be added to decrease any visible tooling marks.

If changes are required to the overmold shape, this could impact the expensive hard tooling that is created. Because of this the project can be impacted by several weeks of delays and cost thousands of dollars. Building a prototype with 3D printed materials is recommended to root out any design challenges before hard tooling is launched.

Looking For a Custom Overmolded Cable?

Discover why Epec's custom overmolded cables are the trusted choice for high-reliability applications across multiple industries. Get insights into our NPI processes, economic pricing, and ready-to-ship inventory.

Request a Quote Request Design Support Request More Information