Optimal Membrane Switch Design For High Reliability Applications

By Paul Knupke - Epec Engineered Technologies

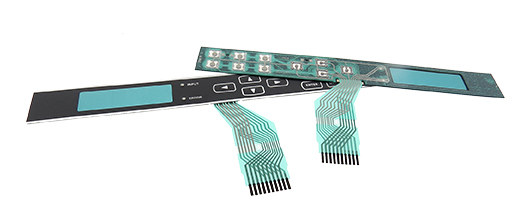

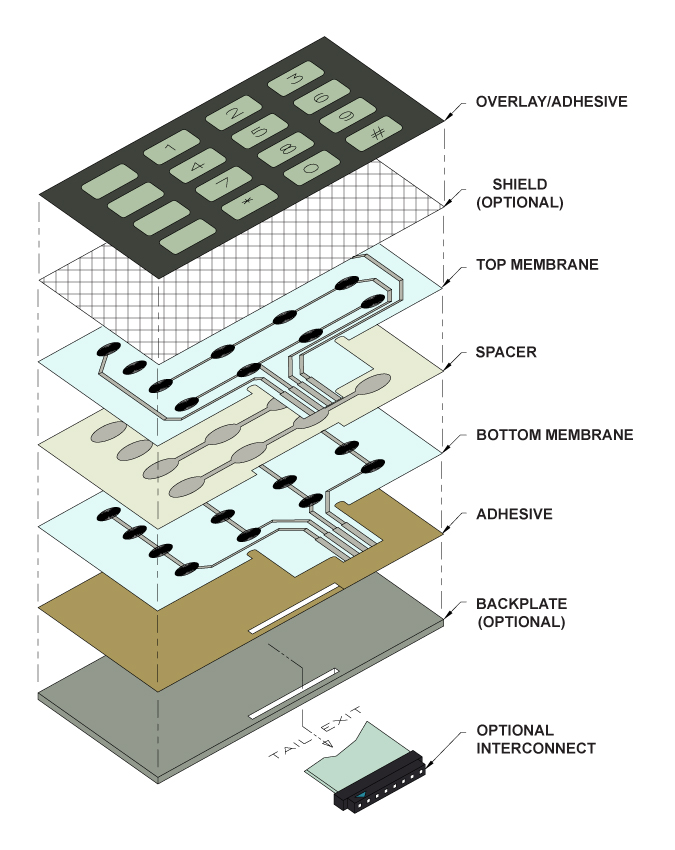

One style of low-profile keypad assembly is the conventional flexible membrane keypad where the switch circuitry is screen-printed. Silver conductive polymer inks are printed onto 1.25 mm (0.005 inches) polyester sheets. Two opposing polyester circuit layers are separated by a thin adhesive/polyester layer with a hole at the switch location. Finger pressure at the switch location deforms the front circuit layer through the spacer hole and completes the circuit to the bottom circuit layer. Tactile feel is provided by a metal snap dome or an embossed dome formed in a polyester sheet, sometimes called poly-domes.

Since the flexible printed membrane switch assembly is a polyester sheet and layered adhesive. The switch assembly is not self-supporting and must be mounted to a rigid support. A common support is a flat metal plate such as aluminum. Large dimension flexible printed membrane switch keypads mounted to metal plates are common in the industry. Larger membrane switches with metal plates can suffer performance and construction integrity problems when used in less than ideal environments.

Performance And Construction Integrity Problems

These problems are generally related to engineering materials selection - Flexible screen printed membrane keypads are all based on polyester sheets with printed silver conductors (See figure 1). Polyester is the only common plastic film that has the physical memory to return to its natural position. After finger pressure is applied, released to close, and open the switch contact surfaces. Other than polyester, common plastic films will permanently deform after repeated operation and will not return to the normal open switch position when finger pressure is removed. Polyester is universally used for screen printed flexible membrane switches because it is the only material that works correctly. The pressure sensitive adhesive used in membrane keypads is acrylic adhesive but there are different acrylic adhesives that can be used. Each acrylic adhesive group has its own characteristics based on performance and cost usually aligns with performance. The lower cost acrylic adhesives are used only for the least expensive. The lowest performance keypads used in “throw-away” applications where life and environmental performance are traded for lower cost.

Figure 1: Screen printed polyester membrane switch with silver conductive ink.

Even the best designed and manufactured flexible screen printed membrane keypads can have problems when mounted to metal support plates where the keypads and metal plates have large dimensions.

The culprit is the difference in the thermal coefficient of expansion between the plastic/adhesive membrane keypad sandwich and the metal support plate. With higher or lower temperature excursions from room temperature the difference in expansion rates causes sheer stress at the interface between the membrane keypad’s rear mounting acrylic adhesive and the metal plate. Acrylic adhesive has better peel strength performance than sheer strength. Repeated stress cycles can cause delamination between the membrane keypad and the metal support plate. Once the delamination starts, there is no practical solution or repair.

Mounted LED Concerns

Sheer stress, vibration, or shock can take a toll on another part of the screen printed membrane keypad. Many membrane keypads incorporate surface mounted LEDs within the membrane sandwich. Printed silver circuits and polyester cannot tolerate soldering temperatures. LEDs are attached to the printed silver circuits with a small amount of silver-filled conductive epoxy.

In a perfect world, attaching and connecting LEDs to printed silver circuits with conductive epoxy sounds like a good idea. However, one of the inherent problems with polyester film used in flexible membrane switches is the peel strength adhesion of hard coat texture inks, graphic ink, or silver-filled ink for circuit conductors is less than desired.

LED failures can occur when stress fractures transpire between the silver ink and the polyester at the LED location or along the silver ink conductor next to the LED. The failure starts to occur as a stress crack which may not cause an open circuit right away. When additional stresses are applied during temperature excursion, shock, vibration, intermittent, open circuits can develop causing the LED to be inoperative. Unfortunately there is no practical repair option.

These LED failures can occur even when the flexible membrane is mounted to a metal support plate. Imagine the reliability problems that can be initiated when LEDs are mounted in unsupported flexible membrane keypads. Unsupported keypads are easily stressed during handling when removed from the shipping box, inspected, inventoried, and kitted for an Original Equipment Manufacturer (OEM) assembly line. Applied stresses may not cause any immediate problems. Moat stress related LED problems do not show up until the product is in the customer’s hands. The later the failure is detected, the higher the total cost is to repair or replace.

Flexible membrane keypads include a flex tail that is part of the same polyester sheet that contains the circuit conductors in the polyester/adhesive keypad sandwich. Creasing, tearing, abrasion or vibration can easily damage the flex tail or the termination point at the end of the tail. The total length of the keypad flex tail plus the size of the keypad itself is constrained by the maximum size of the printed polyester sheet that can be printed.

Figure 2: Standard membrane switch stack-up.

Identifying The Problem

The intent of discussing these problems is to identify the cause of the failures and find a solution. Without knowing the cause of the problem, finding a permanent solution is more difficult. If a part does not stick well to another part, the solution may not be more adhesive. This is a classic engineering materials problem looking for a better solution.

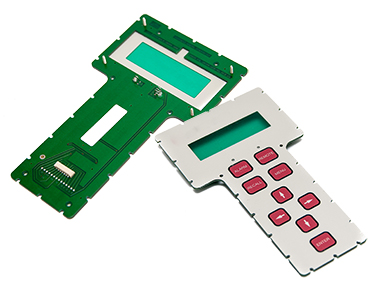

Solution: Transition To Rigid PCB

The best solution involves replacing the parts of the keypad design that caused the problems instead of working around the problems. Epec Engineered Technologies has decades of design and assembly experience with replacing the layered flexible printed membrane with a very thin printed circuit board usually about 0.5 mm (0.020 inches) thick (see figure 3).

Figure 3: High reliability membrane switch with backed rigid printed circuit board.

The printed circuit board is mounted to the metal support plate with high performance acrylic adhesive, similar to a layered flexible membrane keypad. The thermal coefficient of expansion of the printed circuit board laminate is a better match to the metal support plate compared to the polyester/adhesive sandwich. Temperature excursion, shock, and vibration do not cause delamination with the printed circuit board keypad.

The printed circuit keypad assembly can be completed with a graphic overlay, molded rubber keytops, or molded plastic keytops the same as with a printed membrane keypad. The total thickness of the assembly is unaffected as the thin printed circuit board is almost the same thickness as the layered polyester/adhesive.

Additional Benefits Of Using A Rigid Circuit Board In Your Design

- Additional electronic parts can be incorporated into the keypad assembly.

- Surface mounted LEDs can be directly soldered to the printed circuit board, thereby eliminating potential intermittent or open LED circuits caused by stress.

- Keypad interconnections to the application’s electronics are greatly expanded as a wide variety of connectors can be soldered on the rear surface of the printed circuit board through cutouts in the metal support plate.

- Connectors can be high density, through-hole, surface-mounted, polarized, latching, or shielded.

- Electronic components such as resistors, capacitors, diodes, and even integrated circuits can also be mounted to the rear side of the printed circuit.

Summary

In summary, the causes of poor reliability in conventional flexible silver printed membrane keypads have been identified and a good solution has been advanced.

Along with solving the initial reliability problem of flexible printed membrane keypads in mundane environments, using a thin printed circuit board in place of the layered printed polyester/adhesive provides vastly improved interconnection choices.

Incorporating other electronic components in the keypad is also comparable or lower total cost. The improved reliability using a thin printed circuit board in keypads allows the improved user interface keypad to be used in high reliability and harsh environments with improved overall system design, without increasing the cost.

See our blog post on why use a PCB with a membrane switch for more information.

Looking For A High Reliability Membrane Switch Solution?

Our team of experienced engineers is here to help you design a custom user interface solution incorporating LEDs, shielding, and membrane switches with backed rigid printed circuit board.

Request a Quote Request Design Support